Your AI Strategy for Manufacturing Guide

Build a powerful AI strategy for manufacturing with our guide. Discover proven frameworks, real-world examples, and steps to boost efficiency and innovation.

Let's be blunt: having a real AI strategy for manufacturing isn't some futuristic nice-to-have anymore. It's a matter of survival and competitiveness. A proper strategy is what separates companies making meaningful progress from those just running a few flashy but disconnected experiments.

Think of it like building a smart factory. You wouldn't just start pouring concrete and buying robots without a detailed blueprint, right? An AI strategy is that blueprint.

Why an AI Strategy Is Now Essential for Manufacturing

The manufacturing world is moving on from traditional, linear production lines to something far more intelligent and interconnected. In this new reality, an AI strategy isn't just about plugging in new software. It’s about completely re-evaluating how your business operates and creates value.

Without a clear plan, it's easy to pour money into impressive-sounding pilot projects that ultimately go nowhere. They fail because they aren't tied to core business goals. A structured strategy makes sure every AI initiative—from predictive maintenance on the line to optimizing your entire supply chain—is intentional, scalable, and built for a specific purpose. It's the roadmap you need to manage resources wisely and actually see a return on your investment.

The Shift From Reaction to Prediction

For decades, most manufacturing plants have run on a reactive model. A machine runs until it breaks down. Quality control finds defects after a batch is produced. The supply chain scrambles to respond to a disruption after it’s already happened.

A smart AI strategy for manufacturing completely flips this on its head. It moves your entire operation from a reactive stance to a proactive, predictive one.

This is where the magic happens. Instead of just getting better at fixing problems, you start preventing them from occurring in the first place. And the industry data backs this up. As of 2024, 35% of manufacturing firms have already adopted AI in some form. The market itself is expected to explode from $5.94 billion to an incredible $230.95 billion by 2034. You can find more detail on this trend in ArtSmart.ai's manufacturing report.

That kind of growth tells you one thing: manufacturers are moving fast, and those without a plan will be left behind.

A winning strategy moves beyond isolated experiments to create a cohesive, intelligent manufacturing operation. It’s the difference between buying a few smart gadgets and building a truly smart factory. This requires a process of deliberate AI co creation between business leaders and technical teams.

Core Pillars of a Modern Manufacturing AI Strategy

To get this right, you can't just focus on the tech. A resilient and effective plan is built on several fundamental pillars that anchor your technology efforts to real-world business objectives.

This table breaks down the essential components that form the foundation of a successful AI strategy. Think of them as the support columns for your entire smart factory initiative.

Core Pillars of a Modern Manufacturing AI Strategy

Pillar | Core Objective | Key Activities |

|---|---|---|

Business Alignment | Ensure AI initiatives directly improve key metrics like OEE, cost reduction, and product quality. | Map specific business goals to AI use cases. Define exactly how you'll measure success for each project. |

Data Readiness | Create a clean, accessible, and trustworthy data pipeline from the shop floor, MES, and ERP systems. | Perform a thorough data audit. Establish clear data governance policies and invest in the right infrastructure. |

Technology & Infra | Choose and deploy the right platforms, tools, and hardware to run AI models effectively and at scale. | Evaluate cloud vs. edge computing needs. Select the best AI/ML platforms and ensure all your systems can talk to each other. |

People & Skills | Build a team that has the skills to develop, implement, and manage AI systems day-to-day. | Create training programs for existing staff. Hire for specialized roles and cultivate a data-first culture. |

Governance & Ethics | Develop clear, responsible guidelines for using AI securely to ensure compliance and build trust. | Form an AI ethics board. Define data privacy rules and create a solid process for validating AI models. |

Ultimately, getting these pillars right is your best defense against fragmented efforts and wasted investments. This framework provides the clarity and direction needed to build a smarter, more resilient, and more competitive manufacturing operation for the future.

Building Your AI Strategy Framework Step by Step

Creating a winning AI strategy for manufacturing isn't about simply buying the latest and greatest software. It's about methodically building a plan that turns technology's promise into real-world business results. A solid framework is what takes you from scattered, one-off experiments to a coordinated program that can truly scale.

Think of it like building a high-performance engine. You need all the right parts—data, tools, and talented people. But more importantly, you need a precise assembly guide to make sure everything works together to generate real power. This step-by-step process is that guide, ensuring every piece of your strategy is aligned and built for performance.

Stage 1: Assess Your Current State

Before you can chart a course for the future, you have to know exactly where you're standing today. This first stage is all about a brutally honest assessment of your organization's readiness for AI. It's a critical reality check that stops you from building a grand strategy on a shaky foundation.

The goal here is total honesty, not just optimism. A thorough assessment means digging into three key areas:

Data Maturity: Take a hard look at the quality, accessibility, and consistency of your data. Do you have reliable data flowing from your MES, ERP, and IoT sensors? Or is it messy, inconsistent, and locked away in isolated silos?

Infrastructure and Technology: What does your current IT and OT infrastructure look like? Do you have the computing power, network bandwidth, and security protocols in place to handle demanding AI applications?

People and Skills: Honestly gauge the AI and data literacy across your teams. Where are the skills gaps? Who are the potential internal champions who can help drive this change from the inside?

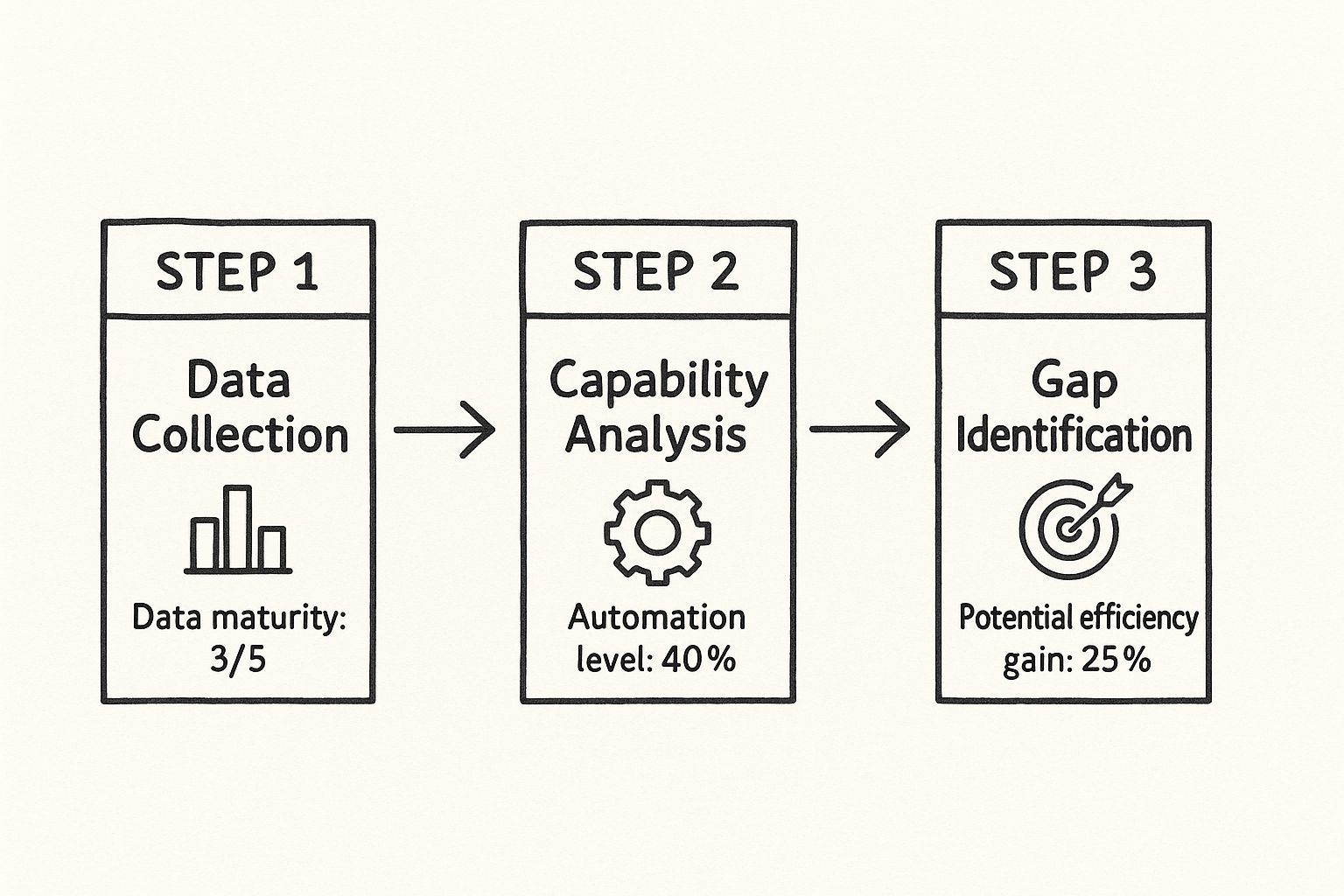

This infographic provides a simple visual for how this assessment process can uncover key opportunities for improvement.

As the visual suggests, analyzing your data maturity and current automation levels will point you directly toward opportunities for major efficiency gains. The gap between where you are and where you want to be is precisely where your AI strategy will deliver the most value.

Stage 2: Define Your Future Vision and Goals

With a clear picture of your starting point, it's time to define your destination. This stage is all about connecting AI directly to your most important business objectives. After all, a vision without clear goals is just a dream, and AI projects without business alignment are just expensive hobbies.

Your vision statement should be ambitious but still grounded in reality. For example, a powerful vision might be: "To become the industry leader in zero-defect manufacturing by using AI-driven quality control." This big-picture vision is then broken down into specific, measurable goals.

A common mistake is setting technology-focused goals, like "Implement three AI models." Instead, you need to focus on business outcomes: "Reduce production line downtime by 15%," "Decrease scrap rates by 20%," or "Improve demand forecasting accuracy by 30%."

These kinds of goals give you clear targets and make it much easier to measure the ROI of your AI initiatives. They transform your AI strategy for manufacturing from a technical exercise into a core driver of the business.

Stage 3: Develop a Realistic and Phased Roadmap

Your roadmap is the bridge that connects your current reality to your future vision. It’s a practical, actionable plan that lays out which AI projects you’ll tackle, in what order, and over what timeline. A great roadmap is all about prioritizing projects based on a smart balance of business impact and feasibility.

A phased approach is almost always the best way to go. Instead of trying to boil the ocean, focus on a sequence of projects where each one builds on the success of the last.

Phase 1: Quick Wins: Start with projects that are low in complexity but high in impact. A predictive maintenance pilot on a single, critical machine is a perfect example. A win here builds incredible momentum and helps secure buy-in for what comes next.

Phase 2: Scaling and Expanding: Take what you learned from Phase 1 and apply it to more complex challenges. This could mean expanding predictive maintenance across an entire production line or implementing an AI-powered visual inspection system.

Phase 3: Transformation: Now you're ready to tackle enterprise-wide challenges, like optimizing your entire supply chain or creating a factory-wide digital twin. These massive projects are only possible because of the data, skills, and technology foundations you built in the earlier phases.

This structured approach is a core part of a proven AI strategy framework. It helps demystify the planning process and guides you in building a realistic path to success by solving well-defined problems first.

Putting AI to Work: Key Use Cases That Are Changing the Factory Floor

Having a solid framework is one thing, but the real magic happens when you translate that strategy into action on the factory floor. This is where the talk stops and the results begin, turning your AI strategy for manufacturing into something that genuinely improves your operations and your bottom line.

Let's move past the planning phase and look at the specific applications that are redefining what's possible in manufacturing today. These aren't just pie-in-the-sky ideas; they are proven solutions delivering real value right now. It's in these applications that the process of AI co creation really shines, as ambitious goals become tangible improvements.

Predictive Maintenance: From Reactive to Proactive

We've all been there. A critical piece of machinery fails without warning, and an entire production line grinds to a halt. The traditional "fix it when it breaks" approach leads to costly, chaotic downtime, emergency repair bills, and a schedule thrown into disarray.

AI-powered predictive maintenance flips this entire model on its head. Instead of waiting for a breakdown, it actively listens for trouble. By constantly analyzing data from IoT sensors—things like vibration, temperature, and even acoustic signatures—machine learning algorithms can spot the subtle, almost invisible patterns that signal a future failure. The system can then alert your maintenance teams days or even weeks in advance.

The Problem: Unplanned equipment downtime kills productivity and inflates repair costs.

The AI Solution: Machine learning models analyze live sensor data to predict equipment failure before it happens.

The Benefit: You minimize downtime, slash maintenance expenses, and see a real boost in your Overall Equipment Effectiveness (OEE).

AI-Powered Quality Control: Catching Every Flaw

Manual quality inspection is a tough job. It's repetitive, subjective, and a momentary lapse in focus can mean a defective product slips through to a customer. That can damage your brand's reputation and lead to expensive recalls. In high-speed environments where defects might be microscopic, the challenge is even greater.

This is where AI-driven computer vision systems come in. Think of them as tireless inspectors with superhuman sight. High-resolution cameras capture images of products moving down the line, and AI algorithms, trained on thousands of examples, can instantly spot the tiniest imperfections—from surface scratches to misaligned parts. They work 24/7 with a level of speed and consistency that's simply beyond human capability.

This isn't a niche technology anymore. It's going mainstream. In the United States, it’s projected that by 2025, over 52% of manufacturers will have integrated AI at some level. We're seeing this trend accelerate in sectors like automotive, where AI handles real-time defect monitoring, and in electronics, where it's used for incredibly complex fault detection. You can learn more about this shift in this insightful report on AI in U.S. manufacturing.

Smarter Supply Chains and Optimized Inventory

Managing a supply chain is a high-wire act. If you overstock, you tie up precious capital and warehouse space. If you understock, you risk production delays and lost sales. Accurately forecasting demand, especially with volatile market conditions, has always been a massive headache.

AI brings a new level of clarity to this chaos. By analyzing huge datasets—historical sales, seasonal trends, real-time market signals, and even things like weather patterns—it can forecast demand with far greater accuracy. An AI system can then automatically trigger procurement orders and optimize logistics to ensure materials show up exactly when you need them.

But it’s about more than just ordering parts. It's about building a supply chain that can bend without breaking. By running simulations of various disruption scenarios, AI can help you find your weak spots and create solid contingency plans before a crisis ever hits. For more inspiration, you can explore a huge library of these applications in our collection of real-world use cases. These examples, often developed with the guidance of AI strategy consulting, show how a smart plan becomes a powerful operational advantage.

How to Navigate Common AI Implementation Challenges

Embarking on an AI strategy for manufacturing is a journey filled with immense promise, but let's be realistic—it's not without its bumps. The key is to see these hurdles not as dead ends, but as predictable challenges you can smooth out with a smart strategy. This approach keeps momentum going and maintains confidence among everyone involved.

One of the first things you'll likely run into is the "productivity paradox." It sounds counterintuitive, but rolling out AI can actually disrupt operations and cause a short-term dip in productivity. A recent study of U.S. manufacturing firms found this "J-curve" effect is quite common. You have to make significant changes to your systems to properly integrate AI, and that initial friction happens before you see the big gains in output and revenue. This is a normal part of the process, and you can learn more about these productivity findings to help set the right expectations from the start.

Taming Your Data and Integrating Systems

Data. It's almost always the biggest headache. Many manufacturers are sitting on data that’s messy, incomplete, or locked away in totally separate systems. Remember, your AI models are only as good as the data they eat, so getting your data in order isn't just a nice-to-have; it's a must.

At the same time, you've got to build a bridge between modern AI platforms and your trusty old operational technology (OT). Your factory floor probably runs on equipment that's been reliable for years but was never designed to chat with a cloud-based AI.

How to Handle the Data: Don't try to solve everything at once. Pick a small, high-value data project to start. Focus on cleaning and structuring that specific dataset. This gives you a high-quality foundation and delivers a quick win, which does wonders for showing everyone the value of good data governance.

How to Handle Integration: Think of middleware and API gateways as translators between your old and new systems. Start with a pilot project that connects a single AI application to one legacy system. Prove it works there before you even think about a factory-wide overhaul.

A smart strategy treats data cleanup not as a one-and-done task, but as an ongoing discipline. It's the groundwork that makes every single AI project that follows easier and more successful.

Managing Costs and Bridging the Skills Gap

Implementing an AI strategy for manufacturing costs money. There are software licenses, cloud computing bills, and the cost of hiring people with very specific skills. Without a clear eye on the budget and a direct line to business value, these costs can spiral out of control and put the whole initiative at risk.

The human side is just as critical. There's a well-known skills gap in manufacturing, and finding people who truly understand both the factory floor and data science is tough. You can't just drop advanced tech on your team and expect magic to happen. They need to be prepared.

Here’s how to tackle these financial and human challenges:

On Managing Costs: Take it one step at a time. Put your initial investment into high-ROI "quick win" projects that can essentially pay for themselves. This proves the value early on and makes it much easier to build a business case for bigger investments down the road.

On Bridging Skills: Invest in training for your current team. Look for enthusiastic employees who can become your "AI champions"—people who can translate between the tech experts and the machine operators. For the really specialized stuff, don't be afraid to partner with outside experts.

Getting past these obstacles is a mix of smart planning, technical know-how, and solid project management. If you need a hand navigating this complex stage, dedicated AI implementation support can provide the structure and expertise to turn your strategy into a reality.

The Technology Stack That Powers Manufacturing AI

An AI strategy is only as good as the technology that brings it to life. Think of it like a high-performance race car—the most brilliant driver can't win without a powerful, finely-tuned engine. In manufacturing, your technology stack is that engine. It’s the collection of tools that work together to turn your ambitious AI goals into tangible results on the factory floor.

The easiest way to think about this stack is in three distinct layers. It all starts with how you gather data, then moves up to where you build the intelligence, and finally, connects to the software that puts that intelligence into action.

The Foundational Layer: Your Data Infrastructure

Everything in AI begins and ends with data. Before a single algorithm can do its job, you need a rock-solid infrastructure to pull in, store, and manage a constant flood of information from your operations. This is the bedrock of your entire AI initiative.

What does this layer look like in practice?

IoT Sensors and Edge Devices: These are your eyes and ears on the factory floor. They’re the sensors capturing real-time data—temperature, vibration, pressure, you name it—directly from your machines. Many modern setups use edge devices to do some initial data processing right there, which cuts down on lag time.

Data Lakes and Warehouses: All that data needs a place to live. Cloud-based data lakes, like Amazon S3 or Azure Data Lake, are fantastic for storing massive amounts of raw, unstructured information. Data warehouses, on the other hand, are better suited for holding structured data that's ready for analysis.

Connectivity and Networking: You need a strong, reliable network (like 5G) to handle the constant stream of data flowing from thousands of sensors back to your central systems. Without it, the whole thing grinds to a halt.

A well-designed data layer is non-negotiable. It’s what ensures the information feeding your AI models is clean, available, and trustworthy, a point we emphasized in our AI adoption guide. Get this part wrong, and nothing else matters.

The Intelligence Layer: AI and Machine Learning Platforms

Once you have your data flowing, you can move up to the intelligence layer. This is where the real "magic" happens—where raw information is crunched and converted into valuable insights through machine learning models. These platforms are the workshops where you build, train, and deploy your AI.

Big names like AWS, Google Cloud, and Microsoft Azure offer powerful suites of AI and machine learning services. They provide everything from pre-built models for common tasks to the heavy-duty tools needed to create custom algorithms from the ground up. The right platform for you will really depend on your existing tech, your team's skills, and what you’re trying to achieve.

The Application Layer: Putting AI to Work

The final layer is where the rubber meets the road. It’s all about connecting this powerful technology to your actual business outcomes. This layer is made up of the specialized software that takes the insights from your AI models and uses them to trigger real-world actions.

For example, your Manufacturing Execution System (MES) might automatically tweak the production schedule based on an AI-powered demand forecast. Or, your ERP system could get a signal to reorder raw materials just before you run out, all thanks to an AI prediction.

This is also where planning tools become invaluable. For instance, our AI Strategy consulting tool can help you match the right technologies to your specific business problems, making sure every dollar you invest has a purpose. To get even more granular, a thorough AI requirements analysis helps you define project specifications with crystal clarity. These resources are designed to close the gap between your vision and the technical steps needed to get there, giving you a solid head start.

Partnering for Success in Your AI Transformation

The road from a great idea to a fully functioning AI strategy for manufacturing is always a challenging one. It's about more than just buying new technology; it's about having a clear vision, a practical framework, and the right expertise to handle the inevitable bumps along the way. From our experience, a well-structured approach is what separates a successful AI initiative from one that never gets off the ground.

This means starting with a solid business case, building a realistic AI strategy framework, and picking your battles by focusing on high-impact projects first. You'll be dealing with everything from messy data and outdated systems to budget limits and the very real need to develop new skills. Getting this right requires a careful blend of deep manufacturing knowledge and serious technical skill.

You Don't Have to Build Your Future Alone

The path to an intelligent factory can feel overwhelming, but it’s not a journey you have to take by yourself. In fact, collaboration is often the secret ingredient that speeds up success and keeps risks in check. Bringing in a dedicated partner can give you the specialized knowledge and outside perspective needed to keep your transformation on track.

This is where expert guidance really proves its worth. Trying to build a complete in-house team with deep experience in both factory operations and advanced AI is a huge undertaking for any company. Partnering for AI co creation gives you immediate access to a pool of seasoned experts, ensuring your strategy is both ambitious and grounded in reality.

The most successful AI transformations are built on a foundation of collaboration. Bringing in focused expertise helps you avoid common pitfalls, make smarter technology choices, and ultimately achieve a faster return on your investment.

Turning Strategy into Tangible Results

A great strategy on paper is just the beginning. The real test is in the execution—turning those plans into working systems that actually boost efficiency, cut down on waste, and give you a real edge over the competition. This is precisely where specialized consulting and tools can make all the difference.

Our approach is built to bridge the gap between your strategic goals and the nitty-gritty of implementation. We offer services and tools designed to support you at every stage:

Expert Guidance: Our AI strategy consulting services bring the industry and technical know-how needed to craft a robust, effective plan.

Strategic Planning: The AI Strategy consulting tool is designed to map specific technologies directly to your business goals, making sure every dollar you invest has a clear purpose.

Precise Specifications: For detailed project planning, our tool for AI requirements analysis helps you define project scopes with absolute clarity—a step we've seen is crucial, as we explored in our AI adoption guide.

Proven Applications: We can help you explore a library of real-world use cases to find proven solutions that will deliver the most significant impact for your unique operations.

By working together, we can shorten your path from an initial concept to a smarter, more resilient manufacturing future. To learn how we can help you build your roadmap and bring your vision to life, connect with our expert team today.

Frequently Asked Questions About AI in Manufacturing

Diving into an AI strategy for manufacturing can feel overwhelming, and it's natural to have questions. Let's tackle some of the most common ones I hear from leaders just like you, so you can move forward with confidence.

How Do I Start Building an AI Strategy with a Limited Budget?

The trick is to think small and targeted, not big and splashy. Don't try to boil the ocean with a factory-wide overhaul. Instead, find one or two specific problems that are causing real pain but aren't overwhelmingly complex to solve.

A great starting point might be predictive maintenance on a single mission-critical machine or using AI for quality checks on one production line. A successful, focused pilot project delivers a clear, measurable return on investment (ROI) quickly. That initial win is your best tool for getting buy-in and a bigger budget for the next phase. The goal is always to solve a real business headache, not just to deploy cool tech.

What Is the Biggest Mistake Companies Make When Adopting AI?

Without a doubt, the most common and expensive pitfall is putting the technology before the problem. This "technology-first" trap happens when a company gets excited about a powerful AI platform and buys it without first defining exactly what business challenge it will solve. This almost always ends in wasted money, frustrated teams, and a failed project.

A smart AI strategy for manufacturing always starts with the business problem. Ask questions like:

What's our number one cause of unplanned downtime?

Where are our most expensive quality control failures happening?

Which link in our supply chain is the most unpredictable?

The answers to those questions are your starting point. Only then should you look for the right AI tool to solve that specific problem. This ensures your investment is tied directly to real-world value from the get-go.

How Can I Prepare My Existing Workforce for AI Integration?

Your mindset should be about collaboration and upskilling, not replacement. Start by identifying the people on your team who are naturally curious and excited about new tools. Turn them into your "AI champions." These folks are invaluable because they can bridge the gap between your technical experts and the operators on the shop floor.

Frame AI tools as assistants that empower your workers to make smarter, faster decisions. For example, an AI system can flag a potential product defect, but the final call is left to an experienced human expert. This approach builds trust, reduces fear, and helps weave AI into your daily operations smoothly.

For more answers to common questions, we've put together a dedicated AI FAQ page.

Ready to move beyond questions and start building your AI-powered future? Ekipa's AI strategy consulting platform can help you uncover and execute your most promising AI opportunities. Get your tailored AI strategy in just 24 hours.