10 Powerful Operational Excellence Strategies to Implement in 2026

Discover 10 powerful operational excellence strategies to boost efficiency and drive growth. Learn how to implement Lean, BPM, and AI for lasting results.

Operational excellence is more than a corporate buzzword; it's a strategic imperative for sustainable growth and a powerful competitive advantage. It represents a fundamental shift in organizational culture, moving from simply completing tasks to systematically improving how those tasks are performed. The goal is to achieve superior performance by embedding principles of efficiency, quality, and customer value into every facet of the business. At the core of transforming operations from good to great is a steadfast commitment to continuous process improvement, ensuring that refinement is an ongoing journey, not a one-time project.

Achieving this state requires more than just good intentions. It demands a structured approach, a clear vision, and the right toolkit. Thriving organizations don't stumble into efficiency; they architect it using proven methodologies. This is where a deep understanding of effective operational excellence strategies becomes critical for business leaders, operations managers, and AI strategists alike. These frameworks provide the blueprint for identifying waste, streamlining workflows, and creating a culture that actively seeks out and eliminates friction. The result is a more agile, resilient, and profitable enterprise.

This comprehensive guide moves beyond theory to provide a practical roundup of the top 10 operational excellence strategies you can implement today. For each strategy, we will break down:

- What it is: A clear and concise definition.

- Why it matters: The strategic business value and impact.

- Measurable KPIs: Key metrics to track success.

- Step-by-step implementation: Actionable guidance to get started.

- Common pitfalls: Mistakes to avoid for a smoother rollout.

- A real-world example: A brief case study for context.

- The AI advantage: How Ekipa AI's AI strategy consulting can accelerate discovery and execution.

This article is designed to be your go-to resource for transforming your operational capabilities, driving significant improvements in performance, and building a foundation for long-term success.

1. Lean Six Sigma

Lean Six Sigma is a powerhouse methodology that fuses two distinct but complementary operational excellence strategies: Lean's focus on waste elimination and Six Sigma's focus on defect reduction. Lean targets the "Eight Wastes" (defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra-processing), while Six Sigma uses a data-driven, statistical approach to systematically remove defects and minimize process variability. Together, they create a robust framework for optimizing efficiency, quality, and customer value.

Why It Matters for AI Transformation

This methodology is particularly potent when paired with an AI strategy. Before deploying expensive AI solutions, Lean Six Sigma helps organizations rigorously identify and quantify inefficiencies in existing workflows. It answers the critical question: "Where will AI deliver the most significant, measurable impact?" By defining problems and measuring performance first, you ensure AI is applied to high-value opportunities rather than automating already flawed processes. This data-first approach de-risks AI investments and guarantees that solutions like AI Automation as a Service are targeted effectively.

Actionable Implementation Steps

- Start Small: Select a high-impact, low-complexity process for a pilot project. This builds momentum and demonstrates value quickly.

- Invest in Training: Certify key team members in Lean Six Sigma (Green Belt or Black Belt levels) to build internal expertise and champion the methodology.

- Define and Measure: Use the DMAIC (Define, Measure, Analyze, Improve, Control) framework to structure your improvement projects. Clearly define the problem, measure current performance with hard data, and establish a baseline.

- Leverage AI for Discovery: Accelerate the Analyze phase with Ekipa's AI requirements analysis process. Our 24-hour discovery service can pinpoint precisely which process inefficiencies are best suited for AI-driven optimization, saving weeks of manual analysis.

- Track Relentlessly: Continuously monitor Key Performance Indicators (KPIs) like Defect Rate, Cycle Time, and Overall Equipment Effectiveness (OEE). Remember, what gets measured gets improved.

A classic real-world example is GE, which, under Jack Welch, used Six Sigma to save an estimated $12 billion over five years by systematically improving processes across its vast portfolio. This illustrates the massive financial upside of embedding statistical discipline into your operations.

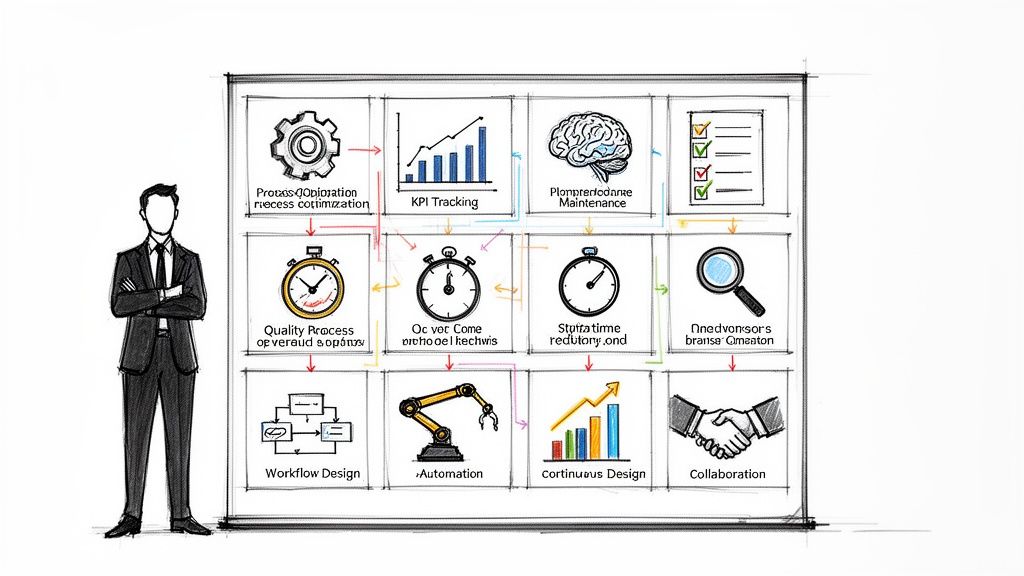

2. Business Process Management (BPM)

Business Process Management (BPM) is a systematic approach to making an organization's workflows more effective, efficient, and capable of adapting to an ever-changing environment. It’s not a one-time task but a continuous cycle of modeling, analyzing, measuring, improving, and optimizing end-to-end business processes. BPM provides a clear blueprint of how work actually flows, moving beyond organizational charts to reveal the cross-functional handoffs, bottlenecks, and redundancies that hinder performance. This visibility is the foundation for meaningful operational excellence strategies.

Why It Matters for AI Transformation

BPM is a critical precursor to successful AI integration. It acts as a diagnostic tool, mapping out the "as-is" reality of your operations so you can strategically design a future "to-be" state enhanced by AI. Without this clarity, companies risk automating chaos or applying AI to low-impact areas. By thoroughly understanding a process, you can pinpoint the exact steps where AI can drive the most value, whether it’s through intelligent data capture, predictive decision-making, or fully autonomous execution. It ensures that investments in technology like workflow automation are precise and yield maximum ROI.

Actionable Implementation Steps

- Document and Visualize: Start by mapping a critical business process from beginning to end. Use standard notation like BPMN (Business Process Model and Notation) to create a visual flowchart. Involve frontline employees in this stage, as they have the most practical knowledge.

- Prioritize for Impact: Analyze your process maps to identify areas with high manual effort, frequent errors, or significant delays. These are your prime candidates for improvement and AI intervention.

- Redesign with AI in Mind: Don't just automate the existing process; reimagine it. Ask, "How could AI fundamentally change the way this work gets done?" This shifts the focus from simple efficiency gains to transformative value creation.

- Implement and Monitor: Deploy the redesigned process, integrating AI tools where identified. Establish clear KPIs such as Process Cycle Time, Error Rate, and Cost Per Transaction to measure the improvement.

- Iterate Continuously: Treat BPM as an ongoing discipline. Regularly review process performance and explore new AI capabilities to drive the next wave of optimization.

A prime example is a major bank that used BPM to map its loan origination process. By identifying data entry and verification as key bottlenecks, it introduced AI-powered document processing, reducing the approval cycle from several days to just a few hours.

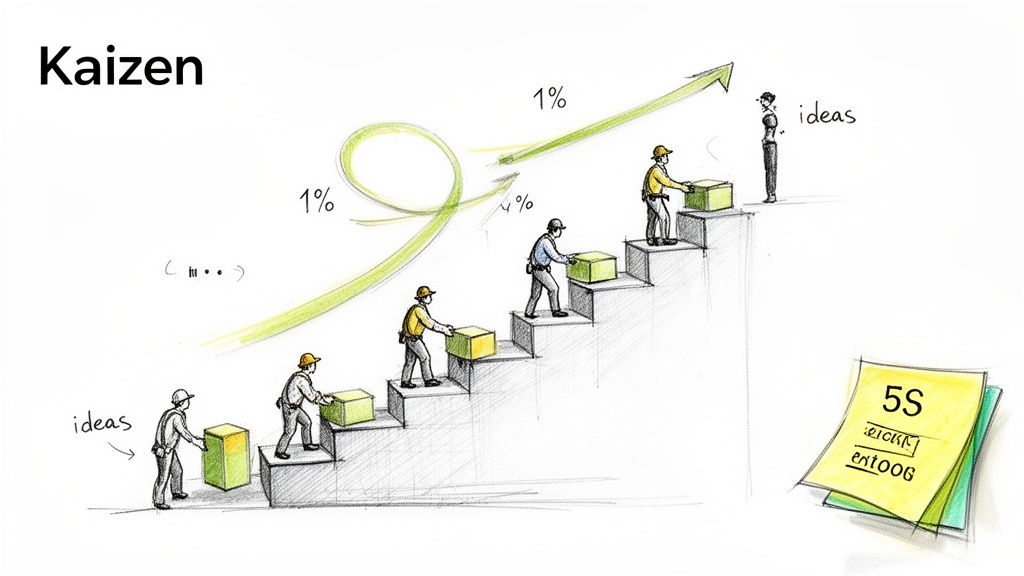

3. Kaizen (Continuous Improvement Culture)

Kaizen is a Japanese management philosophy that translates to "change for the good," focusing on small, incremental, and continuous improvements involving every employee. Rather than pursuing massive, disruptive projects, Kaizen embeds a culture where everyone, from the CEO to the front-line worker, is empowered to constantly identify and implement small enhancements in their daily work. This approach compounds over time, leading to significant gains in efficiency, quality, and morale.

Why It Matters for AI Transformation

A Kaizen culture is the perfect foundation for a successful AI transformation. AI thrives on data and iterative refinement, which aligns perfectly with Kaizen's principles. This culture creates a grassroots engine for identifying high-value automation opportunities that leadership might otherwise miss. Instead of a top-down AI mandate, employees actively suggest where AI can eliminate tedious tasks, improve data accuracy, or streamline workflows, ensuring solutions like AI Automation as a Service solve real, everyday problems and secure organization-wide buy-in.

Actionable Implementation Steps

- Empower Small Changes: Create a simple, accessible system for employees to submit improvement ideas. An "AI Idea Board" or a dedicated Slack channel can work wonders.

- Form Kaizen Teams: Establish cross-functional teams to review suggestions and implement small-scale experiments, fostering collaboration and shared ownership.

- Celebrate Wins Publicly: Acknowledge and reward all contributions, no matter how small. This reinforces the desired behavior and builds momentum for the cultural shift.

- Validate Ideas with Experts: Use Ekipa's AI requirements analysis service to rapidly evaluate employee-generated ideas. We can help you prioritize which suggestions offer the best ROI and are technically feasible, turning grassroots innovation into strategic assets.

- Focus on Rapid Cycles: Implement improvements in weekly or bi-weekly sprints, not quarterly or yearly. The goal is to test, learn, and iterate quickly.

Toyota is the quintessential example, using Kaizen to become a global leader in manufacturing. Its production system empowers every worker to stop the assembly line to fix a problem, embodying the principle that continuous, small-scale quality control is everyone's responsibility and a core driver of operational excellence strategies.

4. Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive management philosophy where quality and continuous improvement are embedded into every single aspect of an organization's culture and processes. Pioneered by figures like W. Edwards Deming, it shifts the responsibility for quality from a specific department to every employee. TQM is built on core principles of customer focus, total employee involvement, process-centered thinking, and strategic, data-driven decision-making. The ultimate goal is to exceed customer expectations by preventing defects and constantly refining operations.

Why It Matters for AI Transformation

In an AI-driven environment, TQM acts as the essential quality assurance framework. It ensures that AI solutions are not just technically functional but also genuinely enhance customer value and align with business objectives. Deploying AI without a TQM mindset risks creating sophisticated systems that solve the wrong problems or deliver a poor user experience. This approach guarantees that quality standards are defined and met throughout the AI lifecycle, from data sourcing and model training to deployment and customer feedback, ensuring that AI enhances, rather than detracts from, operational excellence.

Actionable Implementation Steps

- Define Quality Metrics: Establish clear, measurable quality standards for your AI initiatives. These could include model accuracy, response time, customer satisfaction scores (CSAT) with the AI interaction, or reduction in error rates.

- Empower Cross-Functional Teams: Create teams with members from IT, operations, and customer service to oversee AI quality. Their diverse perspectives ensure the AI solution is robust and user-centric.

- Establish Quality Gates: Integrate quality checkpoints into your AI Product Development Workflow. This includes rigorous data validation, model testing, and user acceptance testing before any solution goes live.

- Leverage End-to-End Execution: Partner with an expert team to ensure your AI solutions are built to the highest TQM standards from concept to deployment. Ekipa's end-to-end tech execution ensures that quality is not an afterthought but a foundational component of the entire process.

- Create a Feedback Loop: Actively solicit and analyze customer feedback on AI-powered services. Use this data to drive continuous improvement and iterate on the solution quickly.

A powerful example is Xerox, which faced intense competition in the 1980s. By adopting TQM principles, the company dramatically improved product quality, reduced manufacturing costs, and increased customer satisfaction, a turnaround that ultimately saved it from bankruptcy. This highlights how an organization-wide focus on quality is a potent operational excellence strategy.

5. Value Stream Mapping (VSM)

Value Stream Mapping (VSM) is a cornerstone Lean technique that creates a detailed visual representation of every step in a process. More than just a flowchart, a VSM documents the flow of both materials and information required to deliver a product or service from start to finish. This powerful visualization tool makes it easy to see where true value is created and, more importantly, where waste and delays are hiding in plain sight.

Why It Matters for AI Transformation

For any business pursuing AI, VSM is the essential first step to building a strategic roadmap. Before you can automate, you must understand the current state in granular detail. VSM provides this clarity, moving beyond assumptions to create a data-backed blueprint of your operations. It pinpoints specific bottlenecks, manual handoffs, and information gaps that are prime candidates for high-impact automation. This prevents the common pitfall of investing in AI tools for business that target low-value or misunderstood parts of the workflow, ensuring a higher return on your technology investment.

Actionable Implementation Steps

- Select a Critical Value Stream: Choose a high-impact process, like customer onboarding or order fulfillment, to map first. Don't try to map the entire organization at once.

- Map the Current State: Involve frontline employees from every step of the process. Walk the physical and digital path of the value stream and document what actually happens, not what you think happens.

- Identify Waste and Bottlenecks: Analyze the map to find the "Eight Wastes," paying close attention to waiting times, rework loops, and unnecessary transportation of information or goods.

- Design the Future State: Envision an ideal process flow with waste eliminated. Use these insights to brief our AI requirements analysis team. We can rapidly identify which parts of your future-state map are best suited for AI-powered solutions.

- Create an Action Plan: Develop a prioritized plan to move from the current state to the future state. Track KPIs like Lead Time, Process Time, and First-Pass Yield to measure progress.

A powerful real-world example is Nike, which used VSM to analyze and streamline its global supply chain. By mapping the entire process from manufacturing to retail, Nike identified major delays and inefficiencies, allowing it to significantly reduce lead times and improve product availability.

6. Theory of Constraints (TOC)

The Theory of Constraints (TOC) is a powerful management philosophy that views any complex system as being limited in achieving more of its goals by a very small number of constraints. It asserts that every process has a single bottleneck, and focusing improvement efforts on that one constraint is the fastest path to elevating overall system performance. Instead of diluting resources by trying to optimize everything at once, TOC provides a laser-focused method to increase throughput.

Why It Matters for AI Transformation

TOC is a crucial framework for any AI strategy because it directly answers the question: "Which single part of our operation, if automated, would unlock the most value for the entire system?" Many organizations mistakenly apply AI to non-critical areas, but TOC forces a prioritization that maximizes ROI. By identifying the primary bottleneck, often a manual, knowledge-intensive, or slow decision-making process, you can deploy AI precisely where it will break the constraint and have a cascading positive effect on the entire value chain.

Actionable Implementation Steps

- Identify the Constraint: Map your end-to-end value stream and pinpoint the single process step that limits the system's output. This is your primary target.

- Exploit the Constraint: Before investing in new technology, ensure the identified constraint is operating at its maximum possible capacity. Eliminate downtime and non-value-added activities associated with it.

- Subordinate Everything Else: Align all other processes to support the constraint. This means other parts of the system should not overproduce or work faster than the constraint can handle.

- Elevate with AI: Use Ekipa’s AI requirements analysis to rapidly determine the best AI solution to break the bottleneck. Whether it's intelligent automation for data entry or a predictive model for decision-making, apply AI to fundamentally elevate the constraint's capacity.

- Repeat the Cycle: Once the constraint is broken, a new one will emerge elsewhere in the system. Immediately repeat the process, fostering a culture of continuous, targeted improvement.

Boeing famously used TOC to slash manufacturing times for its aircraft by identifying and managing bottlenecks in its assembly line, demonstrating how this focused approach drives dramatic results in complex environments.

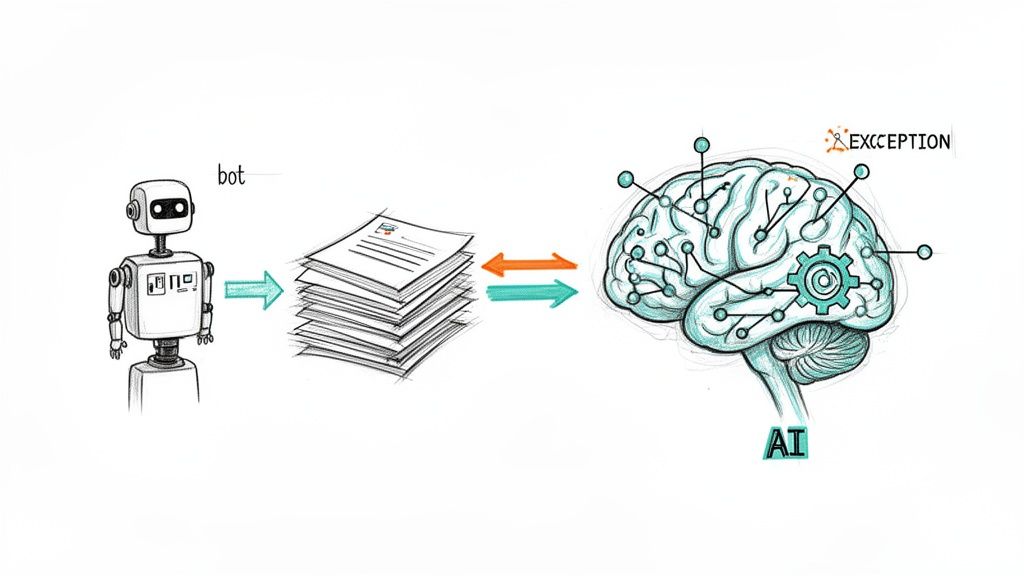

7. Robotic Process Automation (RPA) with AI Integration

Robotic Process Automation (RPA) is a technology that uses software "bots" to automate repetitive, high-volume, and rule-based business processes that humans typically perform. When enhanced with Artificial Intelligence, this evolves into Intelligent Automation, where bots can handle unstructured data, learn from past actions, and manage exceptions. For operational excellence strategies, integrating AI with RPA is transformative; it eradicates tedious manual work, slashes error rates, accelerates processes, and most importantly, liberates human talent for high-value strategic initiatives.

Why It Matters for AI Transformation

Intelligent Automation is a foundational pillar of digital transformation and a direct path to measurable operational gains. Instead of just mimicking keystrokes, AI-powered RPA can interpret invoices, understand customer emails, and make context-aware decisions, turning automation into a dynamic and intelligent workforce. This approach ensures that your AI Automation as a Service investment delivers a direct, quantifiable return by tackling complex workflows that standard RPA cannot. It bridges the gap between simple task execution and genuine process intelligence, making operations more resilient and scalable.

Actionable Implementation Steps

- Identify Prime Candidates: Start with processes that are high-volume, manual, and prone to human error, such as invoice processing or data entry. These offer the quickest wins and a clear ROI.

- Involve Process Experts: Collaborate closely with the employees who perform these tasks daily. Their insights are crucial for designing bots that accurately reflect the process nuances and exception handling rules.

- Establish Robust Governance: From the outset, create a framework for managing your digital workforce. This includes maintaining a bot inventory, implementing change management protocols, and ensuring compliance.

- Inject Intelligence: Use Ekipa's AI expertise to pinpoint where machine learning can elevate simple bots. This could involve adding natural language processing to read support tickets or computer vision to extract data from scanned documents. To further enhance automation, organizations can explore methods for building an AI-powered knowledge base agent to streamline information access.

- Measure Rigorously: Track KPIs like Processing Time Per Item, Error Rate Reduction, and Employee Hours Saved. A clear business case backed by hard data is essential for scaling the initiative.

A powerful example is in financial services, where banks use RPA with AI for transaction processing, often reducing processing times by over 80% while achieving near-perfect accuracy. This demonstrates how Intelligent Automation directly boosts efficiency and compliance.

8. DevOps and Agile Operations

DevOps represents a fundamental cultural and technical shift, uniting software development (Dev) and IT operations (Ops) to shorten the development lifecycle and provide continuous delivery with high quality. It emphasizes collaboration, automation, and rapid feedback loops. Agile Operations extends this philosophy, applying agile principles like iterative development and continuous improvement directly to operational tasks, creating a highly responsive and adaptive infrastructure.

Why It Matters for AI Transformation

This combination is the engine for deploying and managing AI solutions at scale. AI models are not static; they require constant monitoring, retraining, and redeployment based on performance and new data. A DevOps and Agile Operations framework provides the essential CI/CD (Continuous Integration/Continuous Deployment) pipeline to automate this entire lifecycle. This ensures that new AI models and updates can be pushed to production quickly and reliably, allowing the business to iterate and improve AI-driven processes with unprecedented speed, a core tenet of our AI Product Development Workflow.

Actionable Implementation Steps

- Build Cross-Functional Teams: Break down silos by creating teams with members from development, operations, data science, and security. Promote shared ownership and goals.

- Invest in CI/CD Tooling: Implement a robust CI/CD pipeline using tools like Jenkins, GitLab CI, or GitHub Actions. Automate everything from code integration and testing to model deployment and infrastructure provisioning.

- Adopt Agile Ceremonies: Integrate agile practices like daily stand-ups, sprint planning, and retrospectives into your operations and AI development cycles to foster continuous improvement and alignment.

- Implement MLOps: Focus specifically on Machine Learning Operations (MLOps) by establishing automated monitoring for AI model performance, data drift, and prediction accuracy. Set up alerts to flag issues proactively.

- Integrate from Day One: Don't treat DevOps as an afterthought. With Ekipa's end-to-end tech execution, we integrate these operational excellence strategies from the very beginning of your project, ensuring your AI solutions are built for scalability and resilience.

Netflix is a prime example, using its advanced DevOps culture to deploy thousands of changes to its platform daily. This agility allows them to constantly test new features, optimize algorithms, and maintain an exceptional level of service and innovation.

9. Data-Driven Decision Making (Analytics-First Culture)

Data-Driven Decision Making (DDDM) is an organizational philosophy that prioritizes decisions based on empirical evidence and data analysis rather than intuition or tradition. It involves building a culture where data is systematically collected, analyzed, and leveraged to guide strategic and tactical choices. This analytics-first approach creates faster learning cycles and a significant competitive advantage, as seen with pioneers like Amazon and Netflix who use data to relentlessly optimize customer experiences.

Why It Matters for AI Transformation

An analytics-first culture is the bedrock of a successful AI strategy. AI models are only as good as the data they are trained on, and without a solid data foundation, AI investments are likely to fail. This approach ensures that your organization is already collecting and valuing the right information before attempting to build complex AI systems. It establishes the data literacy required to identify high-value AI use cases, accurately measure their impact, and trust the outputs of AI-powered tools. It shifts the focus from "what can AI do?" to "what critical business problem can our data help AI solve?".

Actionable Implementation Steps

- Define Critical Metrics: Start by identifying the Key Performance Indicators (KPIs) that truly drive business success. Don't measure everything; focus on the vital few metrics that reflect operational health and customer value.

- Invest in Data Infrastructure: Establish a "single source of truth" for your data. This could be a data warehouse or lakehouse that makes clean, reliable data accessible to those who need it. This infrastructure is non-negotiable for scaling AI.

- Build Data Literacy: Launch training programs to help business leaders and non-technical staff understand how to interpret data, ask the right questions, and use analytics tools. This democratizes data access and empowers teams.

- Pinpoint AI Opportunities with Data: Use your established KPIs to guide your AI strategy. Ekipa's AI requirements analysis service can analyze your core metrics and operational data to pinpoint which processes will yield the highest ROI from AI automation.

- Test and Learn: Embrace A/B testing and experimentation. Encourage teams to form hypotheses, test them with data, and share the results, whether they succeed or fail.

A prime example is the Oakland A's "Moneyball" strategy, which used statistical analysis to identify undervalued players, completely transforming baseball scouting. This showcases how an analytics-first mindset, one of the most fundamental operational excellence strategies, can disrupt an entire industry by uncovering insights hidden in the data.

10. AI-Enabled Predictive Maintenance and Anomaly Detection

This strategy leverages AI and machine learning to forecast equipment failures before they happen, shifting operations from reactive to proactive. Predictive Maintenance uses historical and real-time sensor data to anticipate breakdowns, while Anomaly Detection identifies unusual patterns in operational data that signal potential issues. Together, they form a powerful defense against unplanned downtime, enabling organizations to schedule maintenance precisely when needed, extend asset lifespan, and improve safety.

Why It Matters for AI Transformation

Predictive Maintenance is a cornerstone of modern industrial AI, transforming maintenance from a costly, reactive necessity into a strategic, value-driving function. For any business with critical physical assets, this approach directly impacts the bottom line by minimizing expensive downtime and optimizing maintenance spend. It allows you to move beyond fixed schedules and "run-to-failure" models, using data to make intelligent decisions that boost Overall Equipment Effectiveness (OEE) and protect revenue streams. This proactive stance is fundamental to achieving true operational excellence.

Actionable Implementation Steps

- Prioritize Critical Assets: Start with equipment where failure carries the highest cost, whether in lost production, safety risks, or repair expenses. Focus your initial efforts here for maximum ROI.

- Aggregate Historical Data: Collect and centralize historical maintenance logs, sensor data (vibration, temperature, pressure), and operational records. This data is the fuel for training accurate predictive models.

- Establish Alert Thresholds: Define clear thresholds for anomalies and predicted failures. Tune these models carefully to minimize false positives, which can erode trust in the system.

- Identify High-Value Opportunities: Leverage Ekipa's use case discovery service to analyze your assets and operational data. We can quickly pinpoint which equipment will benefit most from AI-driven prediction, ensuring your investment is targeted for the highest impact.

- Measure and Refine: Track KPIs like Mean Time Between Failures (MTBF), reduction in unplanned downtime, and maintenance cost savings. Use this data to continuously refine your predictive models, which you can explore further in our predictive maintenance app.

A powerful real-world example is GE, which uses its Predix platform to monitor jet engines and power turbines. By analyzing vast streams of sensor data, GE can predict component failures with high accuracy, saving airlines and utility companies millions in avoided downtime and emergency repairs. This illustrates how AI-enabled maintenance can become a core competitive advantage.

Operational Excellence: 10-Strategy Comparison

| Approach | Implementation complexity | Resource requirements | Expected outcomes | Ideal use cases | Key advantages |

|---|---|---|---|---|---|

| Lean Six Sigma | High — structured methodology and certification | Trained belts, statistical tools, cross-functional teams, time | Reduced variation, measurable cost savings, process efficiency | Complex processes with measurable defects (manufacturing, logistics) | DMAIC rigor, quantifiable ROI |

| Business Process Management (BPM) | Medium–High — process mapping and tool integration | BPM tools/platforms, process analysts, stakeholder engagement | End-to-end visibility, faster automation, improved compliance | Enterprise workflows, regulated processes, digital transformation | Comprehensive process governance and automation readiness |

| Kaizen (Continuous Improvement) | Low–Medium — cultural change and ongoing practice | Employee participation, small investments, facilitation | Incremental gains, higher engagement, continuous improvement | Frontline operations, teams seeking sustained small improvements | Low cost, high employee ownership |

| Total Quality Management (TQM) | High — organization-wide quality systems | Quality frameworks, audits, training, metrics systems | Improved customer satisfaction, consistent quality, reduced defects | Customer-centric businesses, product/service quality focus | Holistic quality focus and standards compliance |

| Value Stream Mapping (VSM) | Low–Medium — visual workshops and analysis | Facilitators, frontline input, simple mapping tools | Clear waste identification, prioritized improvement roadmap | Mapping product/service flows with manual steps | Visual prioritization of high-ROI improvements |

| Theory of Constraints (TOC) | Medium — focused analysis and ongoing attention | Constraint analysis, focused resources, coordination | Rapid throughput gains by addressing bottlenecks | Systems limited by single bottlenecks (manufacturing, services) | High-leverage improvement focus |

| RPA with AI Integration | Medium — bot development plus AI enhancement | RPA platform licenses, developers, governance, AI models | Fast automation of repetitive tasks, reduced errors, quick ROI | High-volume rule-based work with exceptions (finance, insurance) | Rapid deployment, minimal system disruption |

| DevOps & Agile Operations | High — cultural and technical transformation | CI/CD tooling, cloud infra, SRE/DevOps expertise | Faster releases, reliable production, rapid model iteration | AI model deployment, fast-feedback product teams | Continuous delivery and operational resilience |

| Data-Driven Decision Making | High — infrastructure and cultural shift | Data warehouses/lakes, analytics tools, data talent | Better decisions, faster learning cycles, measurable KPIs | Organizations scaling analytics and AI initiatives | Evidence-based decisions and accountability |

| AI Predictive Maintenance & Anomaly Detection | High — sensors, data pipelines, ML models | IoT sensors, data engineers, ML models, maintenance integration | Reduced unplanned downtime, longer asset life, optimized inventory | Asset-intensive industries (manufacturing, utilities, mining) | Proactive failure prevention and fast ROI |

Your Roadmap to Sustainable Excellence

You’ve explored a comprehensive arsenal of ten powerful operational excellence strategies, from the structured rigor of Lean Six Sigma and Business Process Management to the cultural power of Kaizen and the technological leverage of AI-driven automation. We've navigated through the systematic flow analysis of Value Stream Mapping, the bottleneck focus of the Theory of Constraints, and the quality-centric principles of Total Quality Management. The journey continued into the modern era with Agile, DevOps, data-driven cultures, and the predictive power of AI in maintenance and anomaly detection.

The central thread connecting these diverse methodologies is a relentless commitment to creating value and eliminating waste. Operational excellence is not a one-time project or a single initiative; it is an ongoing, dynamic pursuit. It's the cultural heartbeat of an organization that constantly asks, "How can we do this better?" The strategies detailed in this article are not mutually exclusive. In fact, the most successful organizations often weave them together, creating a customized framework that fits their unique context, industry, and goals. For instance, a manufacturing firm might use Lean Six Sigma for process refinement while implementing AI-enabled predictive maintenance to prevent costly downtime.

Key Takeaways for Your Journey

As you move from understanding these concepts to implementing them, keep these core principles at the forefront:

- Culture is the Foundation: A successful transformation hinges on people. Whether you’re implementing Kaizen or fostering a data-first mindset, cultivating a culture of continuous improvement, psychological safety, and employee empowerment is non-negotiable. Without it, even the best tools and processes will eventually fail.

- Technology is a Powerful Enabler, Not a Silver Bullet: AI, RPA, and advanced analytics are transformative. They can automate tedious work, uncover hidden insights, and predict future outcomes with stunning accuracy. However, they are most effective when applied to well-understood and optimized processes. Automating a flawed process only makes you execute a bad process faster.

- Focus on Value, Not Just Efficiency: The ultimate goal of every operational excellence strategy is to deliver more value to the customer. While reducing costs and increasing speed are crucial, these efforts must always be aligned with improving product quality, customer service, and overall satisfaction. Value Stream Mapping is a perfect tool for keeping this customer-centric perspective sharp.

- Start Small, Scale Smart: The prospect of a full-scale transformation can be daunting. Begin with a targeted pilot project. Use the Theory of Constraints to identify a critical bottleneck or apply a VSM exercise to a single, high-impact process. A successful pilot builds momentum, provides valuable lessons, and secures buy-in for broader implementation.

Your Actionable Next Steps

Embarking on this path requires clear, deliberate action. Don't let this knowledge remain theoretical. Here is your immediate plan:

- Assess Your Current State: Where are your biggest pain points? Are they in production bottlenecks, inconsistent quality, or slow decision-making? A simple diagnostic, perhaps using a basic VSM or TOC analysis, will provide a clear starting point.

- Define a Pilot Project: Choose one of the operational excellence strategies discussed and apply it to a single, measurable problem. For example, use a Kaizen event to tackle a specific workflow inefficiency or deploy an RPA bot to handle a repetitive, high-volume task.

- Engage Your Team: Communicate the 'why' behind the initiative. Involve the people who do the work every day in identifying problems and designing solutions. Their insights are invaluable, and their participation is critical for adoption.

- Leverage Expertise and Tools: You don't have to navigate this journey alone. Exploring an AI strategy consulting tool can rapidly accelerate your initial discovery phase, helping you pinpoint the highest-impact opportunities for improvement and aligning them with your business objectives. Our expert team is ready to guide you through the complexities of technology and process integration.

Mastering these operational excellence strategies transforms your organization from a reactive entity into a proactive, resilient, and continuously improving powerhouse. It’s the definitive path to not only surviving market disruptions but leading through them, ensuring sustainable growth and a lasting competitive advantage in an increasingly complex world.

Frequently Asked Questions (FAQ)

What are the core principles of operational excellence?

The core principles of operational excellence revolve around continuous improvement, respect for people, and creating customer value. Key tenets include eliminating waste (Lean thinking), reducing process variation (Six Sigma), empowering employees to drive improvements (Kaizen), and focusing all efforts on delivering what the customer values most.

How does AI enhance operational excellence strategies?

AI acts as a powerful accelerator for traditional operational excellence strategies. It enhances data-driven decision-making by analyzing vast datasets to uncover insights, automates complex and repetitive tasks through Intelligent Automation (RPA + AI), predicts equipment failures before they happen (Predictive Maintenance), and optimizes entire value streams by identifying bottlenecks that are invisible to human analysis.

What is the difference between continuous improvement and operational excellence?

Continuous improvement (like Kaizen) is a core component of operational excellence, but it is not the entire picture. Operational excellence is a broader strategic state where the entire organization, its culture, and its systems are aligned to consistently deliver superior value to customers. Continuous improvement is the ongoing activity that enables and sustains this state of excellence.

Which operational excellence strategy should I start with?

The best starting point depends on your organization's specific challenges. If you have clear quality issues or defects, Lean Six Sigma is a strong choice. If your workflows are poorly understood and inefficient, start with Business Process Management (BPM) or Value Stream Mapping (VSM). If you need quick wins by freeing up employee time, RPA with AI Integration for high-volume tasks is often a great first step.

How do I measure the success of my operational excellence initiatives?

Success should be measured with clear, quantifiable Key Performance Indicators (KPIs) tied to business goals. Examples include:

- Efficiency: Cycle Time Reduction, Cost Per Transaction, Employee Hours Saved.

- Quality: Defect Rate, First Pass Yield, Customer Satisfaction Scores (CSAT).

- Financial: ROI, Cost Savings, Reduction in Unplanned Downtime Costs.

- Culture: Employee Engagement Scores, Number of Improvement Ideas Submitted.

Ready to move from strategy to execution? The journey to operational excellence is complex, but Ekipa AI provides the clarity and tools to accelerate your success. Our platform helps you diagnose operational inefficiencies, identify the most impactful AI and automation opportunities, and build a clear roadmap for implementation. Stop guessing and start building a more efficient, intelligent, and resilient organization today with Ekipa AI. For a deeper dive into our expertise, meet our expert team.