Inventory Management Automation Explained

Discover how inventory management automation reduces costs and boosts efficiency. Our guide covers strategies, tools, and real-world success stories.

Think about the last time you had to do a manual stock count. Poring over spreadsheets, trying to reconcile numbers, and that nagging feeling that something is off. This used to be the only way. For many businesses, it’s a world filled with constant fire drills over stockouts while other items gather dust, tying up valuable cash. It's a system where human error can create inaccuracies as high as 65%. That's not just inefficient; it's a roadblock to growth.

Now, picture a warehouse that runs itself. Orders flow in, stock levels are updated in real-time, and purchase orders are automatically sent to suppliers just before you run out. This is the reality of inventory management automation.

It’s about more than just swapping a spreadsheet for software. It’s a strategic move that frees your team from mundane, repetitive tasks so they can focus on what really matters: growing the business. With the explosion of e-commerce and customers who expect their orders yesterday, automation has shifted from a "nice-to-have" luxury to a core business necessity.

Why Automation Is No Longer Optional

Let's be honest, manual processes just can't keep pace anymore. In a world of one-click ordering and next-day delivery promises, trying to manage inventory by hand is like navigating a superhighway with a paper map—you’re going to get left behind.

The sheer volume and speed of modern commerce demand a smarter system. Automation gives you that real-time visibility and control. Instead of making educated guesses, you're making data-driven decisions that directly boost your bottom line. It's the kind of advantage that has businesses increasingly turning to powerful AI solutions to get ahead.

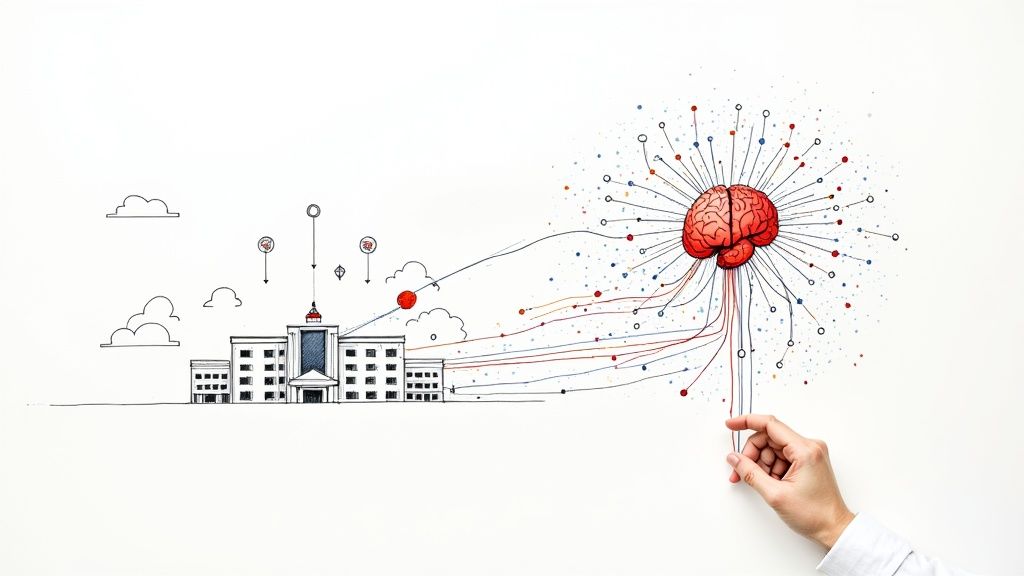

The Strategic Shift to Intelligent Systems

Bringing in automation is a fundamental change in how you operate. It’s not just an IT project; it's about building a supply chain that’s resilient and can react instantly to market shifts. This means thinking beyond simple tracking and adopting a more holistic AI strategy consulting mindset.

By turning raw data into actionable insights, automation transforms your inventory from a passive asset into an active, strategic tool. It lets you anticipate what your customers want, optimize your cash flow, and build a leaner, more profitable business.

This guide will walk you through everything you need to know. We’ll break down the benefits, the technologies involved, and show you some real-world use cases of companies already winning with automation. Whether you're considering a Custom AI Strategy report or exploring AI Automation as a Service, the insights here will give you a solid foundation for success.

The Real Business Impact of Automation

Making the switch to an automated inventory system isn't just a tech upgrade; it’s a strategic move that fundamentally improves your business's financial and operational health. The benefits ripple out far beyond the warehouse, strengthening your balance sheet and even your relationships with customers. You’re essentially shifting from putting out fires to preventing them with smart, data-driven decisions.

One of the first things you'll notice is a dramatic drop in human error. We've all been there—a simple typo can turn an order for 50 units into 500. These kinds of manual mistakes are expensive and disruptive. Automation virtually wipes them out by capturing data electronically, which means your stock counts and financial reports finally become truly reliable.

Slashing Costs and Boosting Cash Flow

Beyond just accuracy, automation takes a direct shot at two of the biggest money pits in any product-based business: high labor costs and sloppy stock management. Think about all the time your team spends on repetitive tasks like cycle counts, generating purchase orders, or pulling reports. Automating these frees them up to focus on work that actually grows the business. It’s not about replacing people—it’s about unleashing their potential.

At the same time, it tackles the classic inventory headaches: overstocking and stockouts. Having too much inventory ties up your cash in products that aren't moving, drives up storage costs, and risks leaving you with obsolete goods. On the flip side, running out of stock means lost sales and unhappy customers.

Effective automation finds that sweet spot right in the middle. By using real-time data to maintain optimal stock levels, it directly improves cash flow, ensuring capital is invested in inventory that sells, not inventory that sits.

A smart approach to workflow automation acts as the engine for this efficiency, turning your inventory into a lean, profitable machine.

Enhancing Customer Loyalty Through Operational Excellence

All these behind-the-scenes improvements have a huge, direct impact on your customers. When your inventory data is accurate, you can give people a reliable "in stock" promise online and get the right order out the door, the first time.

Let’s look at a real-world example. An e-commerce store sees a sudden spike in demand for a hot-ticket item.

- Without Automation: The team scrambles to manually check stock levels, only to find a mismatch. They've oversold. Now they’re stuck spending hours emailing disappointed customers, processing refunds, and dealing with the fallout to their brand's reputation.

- With Automation: The system's real-time tracking stops overselling before it happens. It automatically flags that stock is low, triggers a reorder with the supplier, and updates the website to show exactly what's available. The customer experience is seamless.

Faster, more accurate fulfillment builds trust. When customers know they can count on you to deliver the right products on time, they come back again and again. In today's market, that kind of reliability is a massive competitive advantage. From standard operations to custom ecommerce solutions, accurate inventory is the bedrock of a great customer journey.

Let's break down the core differences in a simple table.

Manual vs Automated Inventory Management

The shift from manual spreadsheets to an automated system represents a leap in efficiency and accuracy. Here's a side-by-side look at what that change really means for day-to-day operations and your bottom line.

| Feature | Manual Inventory Management | Automated Inventory Management |

|---|---|---|

| Accuracy | Prone to human error (typos, miscounts) | 99.9% accuracy with barcode scanning & real-time sync |

| Labor Costs | High; requires significant staff hours for counting & data entry | Reduced; frees up staff for strategic, high-value tasks |

| Visibility | Limited; data is often outdated and siloed | Real-time, centralized view of stock across all locations |

| Decision Making | Based on guesswork and historical reports | Data-driven; based on predictive analytics & demand forecasting |

| Customer Impact | Risk of stockouts, backorders, and fulfillment errors | Improved satisfaction through accurate stock info & fast shipping |

| Scalability | Difficult and expensive to scale as the business grows | Easily accommodates growth in SKUs, orders, and locations |

As you can see, automation isn't just a slightly better version of the manual process—it’s a completely different way of operating that opens up new possibilities for growth and customer satisfaction.

The right internal tooling can connect these dots, ensuring that your operational efficiency translates directly into market success. Our expert team specializes in designing systems that deliver these tangible results.

A Look Under the Hood: The Core Automation Technologies

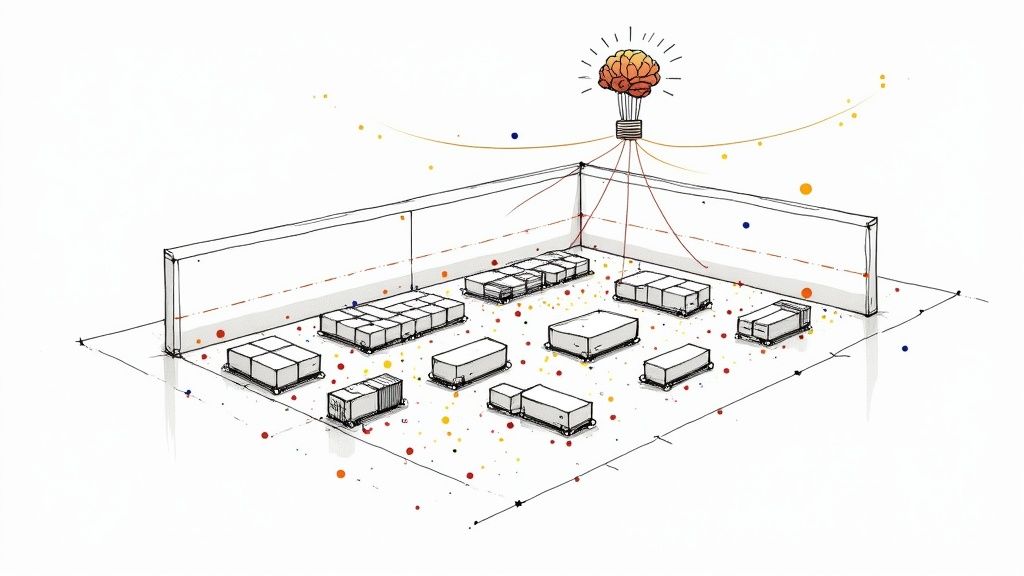

To really get what inventory management automation is all about, we need to pop the hood and look at the engine. The technologies that make it all happen aren't just a jumble of gadgets; they’re a connected system that creates a seamless flow of information from a warehouse shelf all the way to your financial reports. Think of it as building a smart nervous system for your entire supply chain.

It all starts with getting good data. That’s where tools like barcode scanners and Radio Frequency Identification (RFID) tags come in. They are the eyes and ears of the entire operation. While a barcode needs a direct line of sight to be scanned, an RFID tag is a bit more advanced—it can be read from a distance, letting you identify an entire pallet of goods in just a few seconds. This is the first, crucial step in leaving manual errors behind.

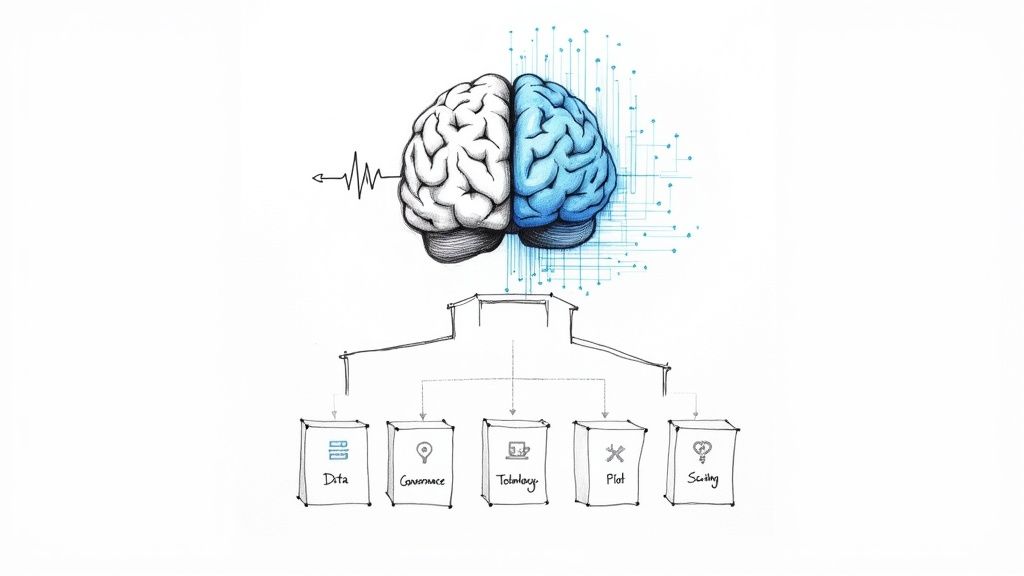

The Software Brains of the Operation

Once you’ve captured all that data, it needs a central hub to make sense of it all. This is where a Warehouse Management System (WMS) comes into play. A WMS is the air traffic controller for everything happening within your warehouse walls, directing picking, packing, shipping, and receiving. It ensures every single item is tracked from the moment it arrives until the second it leaves.

But a WMS doesn't work in isolation. It plugs into a much broader Enterprise Resource Planning (ERP) platform. The ERP is what connects your inventory data to the rest of the business—accounting, sales, procurement, you name it. This integration means that when an item is sold online, the information flows automatically, updating your books and triggering reorder alerts without anyone having to lift a finger.

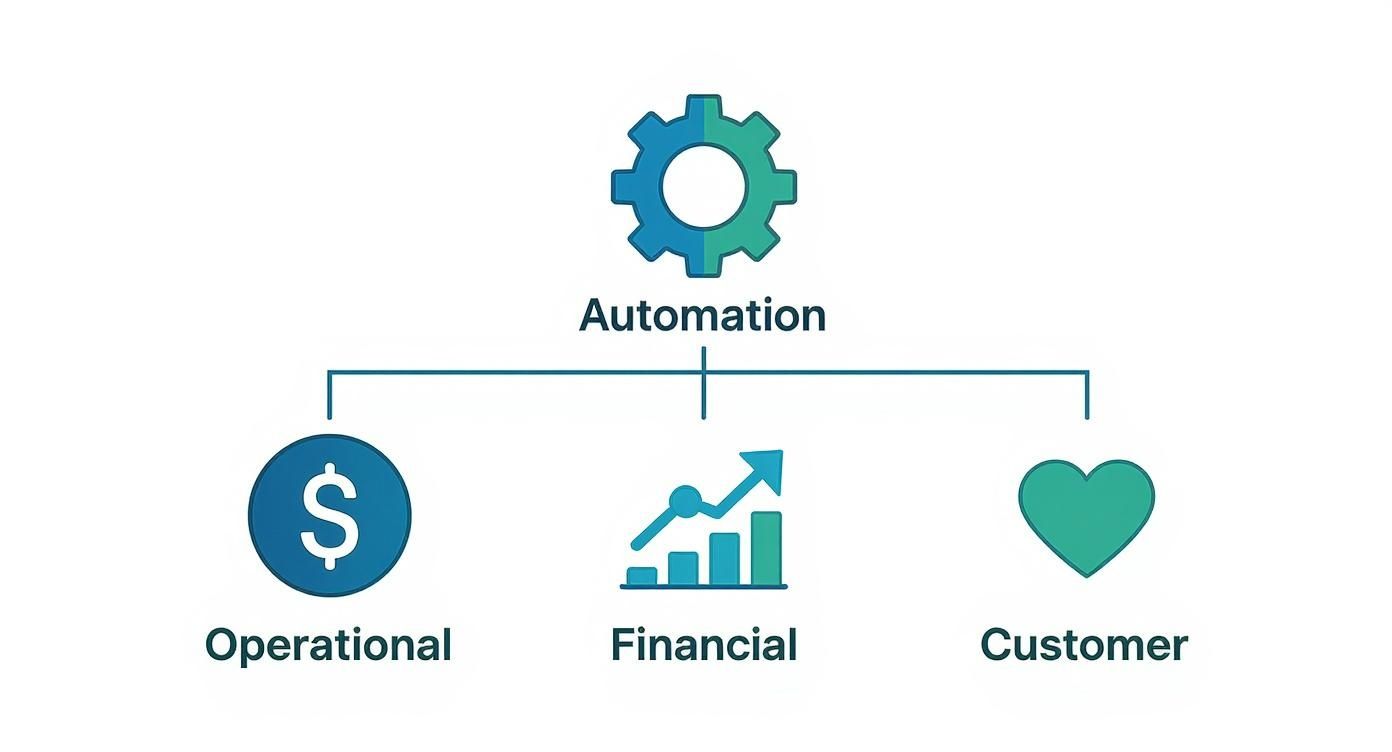

This infographic shows how automation isn't just a warehouse tool; its impact ripples out, touching operational, financial, and customer-facing parts of the business.

As the diagram makes clear, automation is the foundation. When you build on it, you drive improvements across the entire company, not just in one siloed department.

The Real Game-Changer: AI and Machine Learning

Here’s where automation gets truly intelligent. If a WMS is the brain, then Artificial Intelligence (AI) and Machine Learning (ML) are its ability to learn, predict, and reason. These advanced systems crunch massive amounts of data to spot patterns a human could never see.

The growth in this space is staggering. The inventory management software market is projected to hit USD 4.79 billion by 2032, and that growth is almost entirely fueled by these intelligent capabilities. The industry is racing to catch up, with 77% of retailers aiming to have real-time visibility by 2025. They're trying to escape the old manual methods that cause errors in a shocking 43% of warehouses. You can read the full research about these market trends on fortunebusinessinsights.com.

AI-powered systems are incredible at predictive analytics for demand forecasting. It’s like having a hyper-accurate weather report for your sales. Instead of just looking at last year's numbers, it analyzes market trends, seasonal spikes, and even the potential impact of a marketing campaign to predict what customers will want. This is a key piece of our proven AI Product Development Workflow.

These essential AI tools for business are what turn raw data into smart, automated actions that drive your business forward.

An AI-driven system doesn't just tell you that a product is selling fast. It proactively calculates the perfect reorder point, factoring in supplier lead times and shipping costs, and can even automatically generate a purchase order to prevent a stockout before it's even a remote risk.

This kind of foresight is what separates a supply chain that’s always playing catch-up from one that’s proactive and always one step ahead. It gives you the power to anticipate customer needs and market shifts, which is a massive competitive advantage.

How to Bring Your Automation Strategy to Life

Moving to an automated system isn't like flipping a switch. It’s a deliberate process that requires a clear plan, starting with a hard look at where you are now and a solid vision for where you want to be. Thinking methodically is the only way to make sure your investment in technology actually pays off and truly changes your operations for the better.

The first step is a thorough audit of your current inventory processes. This goes way beyond just counting boxes on a shelf. You need to map out every single touchpoint in your inventory's journey, from the moment a shipment arrives at your dock to the second it leaves for a customer. The real goal here is to find the friction points. Are typos from manual data entry causing constant errors? Are your warehouse pickers taking inefficient routes? Nailing down these specific pain points is the key to choosing the right automation tools to fix them.

Set Goals You Can Actually Measure

Once you know what’s not working, you can set clear goals for what you want to achieve. Vague ambitions like "get more efficient" are useless. You need to get specific and set targets you can actually track.

- Slash Costs: Aim to cut your inventory carrying costs by 15% in the next six months by keeping stock at optimal levels.

- Boost Accuracy: Target a 99.5% order accuracy rate within the first three months after you go live.

- Ship Faster: Work to cut your average order fulfillment time down from 48 hours to just 24.

Having concrete goals like these will shape your entire strategy, from the software you choose to how you train your team. They give you a clear benchmark for what success looks like and keep everyone pulling in the same direction.

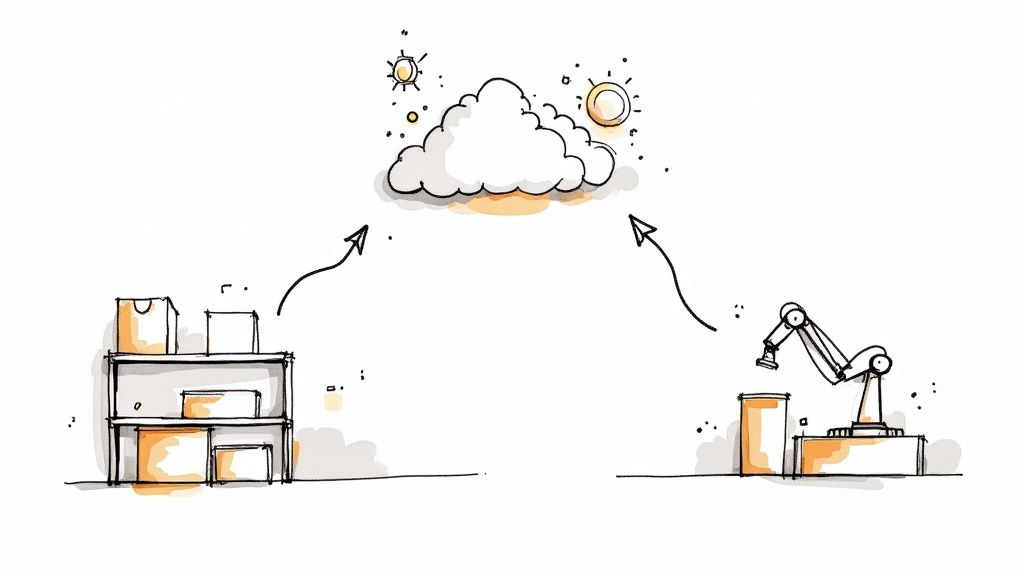

Choose the Right Tools for the Job

With your goals locked in, it’s time to look at hardware and software. This isn't about buying the flashiest, most expensive system on the market. It’s about finding the perfect fit for your specific operation, budget, and size. A small online store might just need a simple cloud-based inventory app, while a massive distribution center will require a full-blown Warehouse Management System (WMS) that integrates with robotics.

A huge piece of this puzzle is figuring out data migration and system integration. Your new system has to talk flawlessly with everything you already use, like your e-commerce platform, accounting software, or ERP. A botched integration can cause a world of headaches and create more problems than it solves. Making sure all your systems connect is a fundamental part of effective workflow automation, as it allows data to move freely across your entire business.

Here’s a pro tip: Roll out your new system in phases. Start with the process that causes the most pain—like receiving or picking—and get a quick win. This builds momentum and shows your team the real value of the investment right away.

As you map everything out, make sure your plan aligns with the latest essential inventory management best practices to set yourself up for success.

Don't Forget the People

Technology is just one half of the story; your team is the other. A smooth transition depends entirely on good change management and great training. Start by explaining the why behind the new system. Frame it as a tool that will make their jobs easier and more meaningful, not as something that’s there to replace them.

Then, provide hands-on training that builds real confidence and skill with the new tools. When you empower your team to become advocates for the new system, you're on the right track. This people-first approach is central to our proven AI Product Development Workflow, which is built on collaboration and clear communication for navigating big projects. When you invest in your people, you guarantee the technology isn't just installed—it's embraced and used to its full potential for years to come.

Taking Inventory Optimization to the Next Level with AI

If basic automation is about working more efficiently, then intelligent optimization is about gaining a real competitive edge. This is where inventory management automation gets truly interesting. We're moving beyond simple, repetitive tasks and into a world where Artificial Intelligence starts to think, predict, and adapt on its own. It’s a shift that turns your supply chain from a reactive process into a proactive, intelligent engine for your business.

At the heart of this change is AI-driven demand forecasting. Traditional methods are a bit like driving a car while only looking in the rearview mirror—they rely almost entirely on past sales data. AI, on the other hand, looks at the road ahead. It crunches an incredible amount of data—not just past sales, but also market trends, competitor pricing, upcoming holidays, and even social media buzz—to create forecasts that are remarkably accurate.

This predictive capability is why the global inventory optimization market is projected to more than double, growing from USD 5.87 billion in 2025 to an estimated USD 12.42 billion by 2032. Businesses are quickly catching on, adopting data-driven systems that use real-time analytics to make smarter decisions on the fly. You can read more about these market dynamics on coherentmarketinsights.com.

Strategic Stock Placement and Dynamic Pricing

AI's smarts don't just stop at predicting what customers will buy. It also figures out the best way to get those products to them. For any business running multiple warehouses or distribution centers, AI can optimize where you keep your stock across the entire network.

It weighs factors like shipping costs, delivery times, and regional demand spikes to tell you exactly how much of each product to store in every location. This kind of strategic placement means you can meet—and even beat—customer expectations for fast shipping, all while keeping your logistics costs down. This is a core part of what we focus on with our approach to AI Automation as a Service.

Beyond logistics, AI also unlocks dynamic pricing strategies that react instantly to what’s happening in the market.

- Hot Sellers: If an item is flying off the shelves, the system can suggest a small price bump to maximize your profit.

- Slow Movers: For products gathering dust, AI can recommend a promotional price to clear them out and free up cash.

- Competitor Moves: The system can even keep an eye on what your competitors are charging and adjust your prices in real time to stay competitive without killing your margins.

When you connect your inventory levels directly to your pricing, AI ensures you're never leaving money on the table or losing a sale because your price was a dollar too high.

Building a Supply Chain That’s Ready for Anything

Using these advanced AI techniques is about building a supply chain that isn't just efficient, but also resilient. It's about creating a system that can see disruptions coming, adapt to sudden changes, and grab opportunities automatically.

Getting to this level of intelligent automation takes a clear vision and a solid plan. That's why services like our AI strategy consulting and a Custom AI Strategy report exist—to help businesses map out this journey. By integrating these powerful AI solutions, you're not just improving your inventory management; you're building a future-proof supply chain that actively drives your success.

Seeing Inventory Automation in Action: Real-World Success Stories

It's one thing to talk about theory and strategy, but the real proof is always in the results. Seeing how other businesses have put inventory management automation to work shows just how powerful it can be. These stories aren't about small tweaks; they're about completely rethinking what a business can achieve.

Let's look at a few real-world use cases that bring these benefits to life.

E-commerce Retailer Masters Seasonal Demand

For one online fashion retailer, the holiday season used to be a recurring nightmare. Huge spikes in demand would completely overwhelm their manual inventory process. This led to the worst of both worlds: popular items would sell out instantly, while other products gathered dust, tying up cash in costly overstock.

Throwing money at the problem by hiring temps wasn't a great solution, either. It was expensive and often led to even more human error.

By bringing in an automated inventory system, they completely turned things around.

- Real-Time Syncing: The new system kept inventory levels perfectly synchronized across their website and all other sales channels. No more accidentally overselling hot items during a flash sale.

- Predictive Reordering: AI dug into their sales history and current trends to forecast which items would become holiday best-sellers. It then automatically placed purchase orders so they never ran low.

- Efficient Fulfillment: The system generated optimized pick lists for the warehouse crew, dramatically cutting the time it took to pack and ship orders.

What was the outcome? The company handled a 40% increase in holiday orders without adding staff, pushed order accuracy to an incredible 99.8%, and saw customer satisfaction scores soar.

Manufacturer Slashes Production Delays

A mid-sized electronics manufacturer was constantly battling raw material shortages. Without a clear view of their stock, they’d often run out of a critical component mid-production. This brought the entire line to a halt, causing frustrating delays and serious financial hits.

They decided to integrate an automated system that tracked every piece of raw material, from the moment it arrived to its use in final assembly. This gave them a crystal-clear picture of their supply chain.

This newfound visibility allowed them to confidently switch from a costly "just in case" inventory model to a much leaner "just in time" approach. The shift cut their raw material waste by a whopping 25% and made production delays due to stockouts a thing of the past.

Logistics Provider Achieves Near-Perfect Accuracy

When you’re a third-party logistics (3PL) provider, your entire reputation is built on speed and accuracy. Even tiny error rates in picking and packing can sour client relationships and ruin your good name. To protect their reputation, one 3PL provider invested heavily in warehouse automation, bringing in robotics and AI-powered vision systems.

Today, autonomous mobile robots (AMRs) zip through their warehouse, retrieving goods under the guidance of an intelligent management system.

This move puts them at the forefront of a massive global trend. The warehouse automation market is projected to jump from USD 29.91 billion in 2025 to USD 63.36 billion by 2030. It’s no wonder why—solutions like AMRs often deliver an ROI over 250% in just two years. Of course, hurdles like ROI concerns (40%) and staff training (37%) remain. You can discover more insights about these warehouse statistics on clickpost.ai.

For this 3PL provider, the investment paid off handsomely. They now boast a picking accuracy rate of 99.9%, faster fulfillment times, and significantly lower labor costs. Integrating with their clients’ specialized custom ecommerce solutions is now a breeze, cementing their status as an industry leader. These are the kinds of measurable, high-impact results our expert team delivers every day.

Building Your Smart Supply Chain

We've covered a lot of ground here, from the nuts and bolts of inventory automation to the strategic thinking behind it. If there's one thing to take away, it's this: automating your inventory isn't just a nice-to-have anymore. For any business that wants to grow and stay competitive, it’s a must-do. The real goal is to free your team from the grind of repetitive tasks, allowing them to focus on the strategic work that humans do best.

Ready to take that first step? A great place to start is by looking at how individual pieces of your supply chain fit together. For instance, you can dig deeper into streamlining procurement workflows with automation. Adopting this wider view is how you begin to build a genuinely intelligent operation from the ground up.

This is exactly where we come in. We specialize in creating custom internal tools that make a real difference in how your business runs. The principles of smart inventory management are especially critical for improving manufacturing efficiency, a sector we know inside and out. You can learn more about our work here: https://www.ekipa.ai/industries/manufacturing.

Let's start a conversation about what your roadmap to success could look like. Connect with our expert team, and together, we can build a smarter, more resilient supply chain.

Frequently Asked Questions

We get it—diving into automation brings up a lot of questions. Here are a few of the most common ones we hear, with straight answers to help you see the path forward.

What’s This Going to Cost Me?

The price tag on inventory automation can swing wildly. A small e-commerce shop might get started with a solid cloud-based system for less than $100 a month. On the other end of the spectrum, a massive warehouse looking at robotics is making a serious capital investment.

The real question isn't about cost, but about return on investment (ROI). Good automation doesn't just cost money; it saves money by cutting down on expensive errors, wasted labor, and sales lost to stockouts. Most systems pay for themselves within a year or two. The smartest way to start is with an audit to find where you'll get the biggest bang for your buck first.

Am I Too Small for This?

Not a chance. In fact, for small businesses, automation is one of the most powerful tools for growth. There are tons of scalable, cloud-based systems built specifically for small and mid-sized businesses, with affordable plans you can adjust as you grow.

As we explored in our AI adoption guide, getting automation in place early stops bad manual habits from taking root. It sets you up to handle a surge in orders without drowning in spreadsheets and frantic stock counts.

Will Automation Make My Team Obsolete?

This is a common fear, but the goal is almost always to empower your team, not replace them. Think of it as giving them superpowers.

Automation is brilliant at the tedious, repetitive stuff humans hate anyway—like counting widgets for the thousandth time or generating purchase orders. This frees up your people to focus on the things that require a human brain: spotting quality issues, solving tricky logistical puzzles, and making sure customers are happy.

How Long Until I’m Up and Running?

The timeline really depends on what you're trying to do. If you're plugging in a simple cloud software, you could be live in just a few days.

But if you're overhauling a large warehouse with a full-blown warehouse management system (WMS) and new hardware, you're likely looking at a project spanning several months. A phased rollout is usually the best approach. Tackle your biggest pain point first, get a quick win, and make the transition smoother for your whole team. For a detailed look at what an implementation could look like for you, our expert team can map it all out.

Ready to stop guessing and start running your operations with intelligent automation? At Ekipa AI, we build custom tools and strategies that turn your inventory data into your biggest competitive edge.